If there is one thing that large industrial companies are concerned about, it would have to be safety. Operating a safe working environment is extremely important for several reasons. As a result, businesses all over the world incorporate safety guidelines are created, but these are not always enough to prevent accidents. Companies have to go to great lengths to keep things safe. If you own a company that is concerned about safety, then keep reading. You might be able to get some ideas. Here are some of the top ways companies all over the world are keeping things safe for their employees.

Safety Training

One of the best ways to ensure that everyone is safe while performing their job is with the proper training. The more extensive the training is, the less chance there will be for any type of accidents. This is the best way to keep a work place free of accidents.

Some companies will go send their employees to trade specific schools. Some will make their employees watch safety videos and others will give their employees hands on safety training that will let the employees learn from example. Every training method has its pros and cons. The bottom line is this. Whichever training method works best for your employees is the best training method to use.

Personal Safety Equipment and Clothing

Some companies will supply their employees with safety gear that helps protect them while they are working. Some of the more common safety gear would be: safety glasses face shields, gloves, boots, and protective suits. These items should be worn at all times in order to prevent any accidents from occurring during work hours. The more safety gear a company can supply their employees, the safer their employees will be. Safety gear coupled with the right safety training may be all that is needed to keep an industrial work place free from dangerous accidents.

Safety Switches

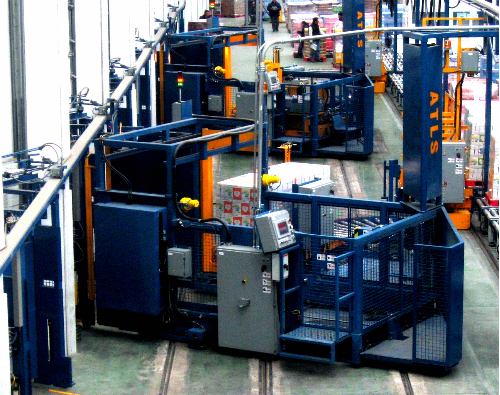

No industrial facility would be complete without the use of safety switches. These are the big green or red switches that allow machinery to be started or stopped. In most cases, safety switches have to do with shutting something down in order to prevent an accident. These are the large read emergency shut off buttons that anyone in the facility can operate.

A key switch could be the key to safety in industrial facilities.

Image credit: wiki commons ATLSINC

There may be other safety switches that only certain people have access to. These switches may be the ones that power up large industrial equipment. Keeping these switches safe may require something like a key. The most common type of switch in this case is called the Key switch, and just like the name suggests, a key is required in order to operate this switch. This specific type of switch can come in a wide variety of mounting types and actions. They may also require accessories like covers, and no key switch would operate without a key.

Bringing These Three Things Together

Each of these safety methods by themself can help to keep the work place safe and free from any type of accident. If a company combines all three of them together, they may be able to create the safest working environment in the world.