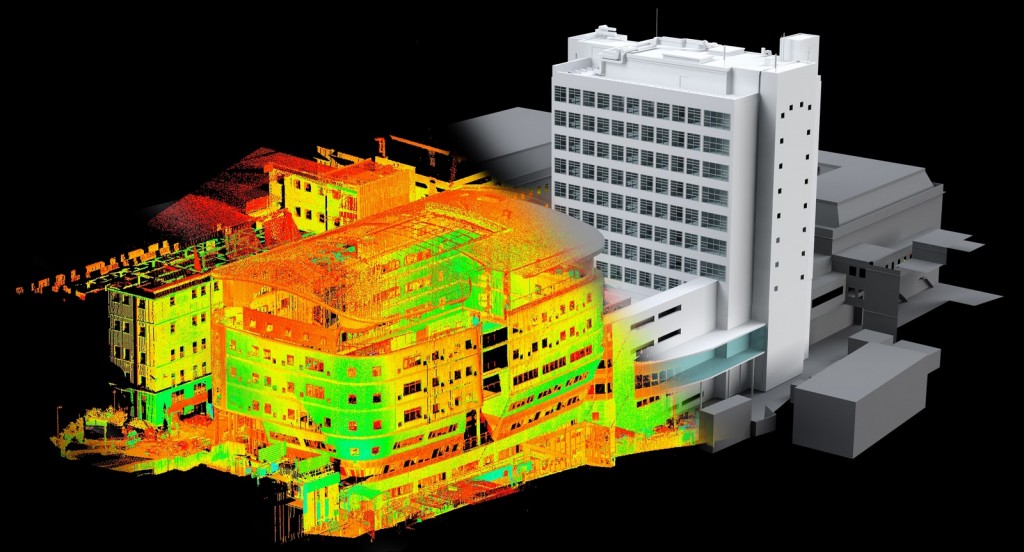

What is Laser Scanning?

Laser scanning is a process used for various engineering projects such as the construction of architecture, airports manufacturing plants, turnkey hospitals, bridges and many other types of infrastructure. Virtually all modern capital projects require rigorous design review before finalisation. Laser scanning is used to rapidly and accurately capture shapes of buildings, objects and landscapes and has proved to be an invaluable asset for Nigeria’s turnkey hospitals’ completion; it reduces data collection errors and saves time and money, with a degree of accuracy previously impossible.

Methods

3D laser scanning technology is a valuable tool for the reduction of construction costs by reducing or eliminating design errors worth thousands of dollars in project delay costs. This process determines whether designs are ready for construction or execution. 3D laser scanning collects precise information and lowers processing time, and this is one of many reasons why it has become vital to the construction of turnkey hospitals

Benefits

Laser scanning has been tremendously beneficial in the construction of turnkey hospitals. These benefits include, but are not limited to:

- Improved safety of turnkey hospitals, as construction, maintenance, and renovations had been traditionally assessed with manual techniques. Laser scanning has improved our ability to localise damage and make repairs as needed. This, in turn, reinforces the safety and efficiency of our hospital facilities, reducing design and construction errors and providing safer turnkey hospitals overall.

- Contractors now see lower cost systems as the future for turnkey hospitals in Nigeria and are able to perform renovations and additions while retaining both flexibility and accuracy.

- More accurate retrofit projects (the addition of new technology or features to older systems) have been made more available, such as outfitting existing buildings with energy efficiency equipment, and strengthening older buildings in order to make them resistant to natural disaster.

- Reduced cycle time has enabled organisations to work more efficiently because of error reduction, safety implementation and quality construction and maintenance. Laser scanning offers more efficient construction over less time and thus, at a lower cost.

- The construction process runs more flexibly and efficiently through complex pipelines because of laser scanning.

Spanning its 16-year history, Deux Projects International has delivered more than 30 major civil and building construction projects, learning from their successes in the meantime.

Nigeria has particularly benefited from laser scanning techniques both in the oil industry and urban renewal where they have been used to great success by companies like Deux Projects and their CEO, Dr. Tunji Olowolafe (also known as Olatunji Olowolafe). There have been tremendous improvements and maintenance of Nigeria’s turnkey hospitals.

Dr. Olowolafe has been helping to build and maintain hospitals and research facilities for a number of years and has made great strides in improving the overall standards of Nigeria’s healthcare system. Nigeria has mastered the arts of ad science, urban renewal and demolitions projects. Deux Projects has also built a stadium in preparation for the Junior World Cup Soccer event in Nigeria. With organisations like Deux Projects International, Nigeria will soon be raising the standards for everything, from sporting facilities to the healthcare system, and everything in between.

Written by: Abiola Alabi is a Nigerian blogger, journalist and writer. He is particularly interested in infrastructure development and urban renewal in and around the burgeoning metropolis of Lagos, Abiola closely follows the work of Dr. Tunji Olowolafe CEO of Deux Project Ltd focusing on the long term gains in economic development that comes with improved healthcare standards and the infrastructure developments needed.